AM-Studio - Data processing software for additive manufacturing

AM-Studio offers an advanced and user-friendly solution for additive manufacturing. This high-end platform supports users from the initial concept to final post-processing. State-of-the-art algorithms and automated functions facilitate the analysis of components, the creation of support structures and the slicing and hatching processes

AM-Studio is the additive manufacturing solution for beginners, advanced users and experts

Whether you are entering the world of 3D printing or are an expert looking to push the boundaries of additive technologies, AM-Studio enables a significant reduction in time-to-print in various application areas. The software is flexibly available: as a stand-alone solution, as a seamlessly integrated version in PTC Creo® or as a customized version for specific industries.

High-end in terms of functionality, but still easy to use

AM-Studio is an extremely powerful data processing software for additive manufacturing which, despite its unique range of functions, remains easy to use even for newcomers to 3D printing. This is because users are guided step-by-step through the manufacturing process from importing data and selecting the material, production machine and zero-point clamping system through to post-processing.

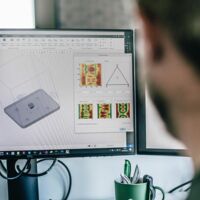

Self-explanatory graphical user guidance

In addition, a self-explanatory graphical user interface as well as algorithms and automatisms running in the background support the achievement of objectives. The heart of this comprehensive additive manufacturing solution is therefore a high-end build processor, whose computing capabilities allow even the most complex geometries to take shape in record time - with minimal resource requirements. A hard disk capacity of at least 10 GB and a working memory of 2 GB are recommended for the slicer/hatcher. AM-Studio itself requires 16 GB of RAM, but twice that is recommended. Further details on the system requirements can be found here.

Software that thinks for itself

AM-Studio is a forward-thinking software that offers features often overlooked in other solutions or only available as paid add-ons. By default, AM-Studio includes an advanced healing function that automatically repairs damaged STL files.

Pre-deformation tool for perfect components

In addition, it offers an innovative pre-deformation tool that uses finite element analysis to calculate how a component must be intentionally printed so that it comes out of the machine perfectly in line with requirements. Another outstanding feature is the AM-LOCK configurator, which makes it possible to segment the build plate according to specific requirements.

AM-LOCK configurator for segmenting the construction panel according to requirements

AM-LOCK, a versatile zero-point clamping system from pL LEHMANN, is designed for the entire manufacturing process and is used from preparation to final 3D printing and subsequent steps such as machining, Hirtizing® or measuring. AM-Studio provides the digital platform for this comprehensive application across different manufacturing domains. A special feature is the automated post-processing method called Hirtizing, which facilitates the removal of support structures using chemical, dynamic electrochemical and hydrodynamic methods. This method is already integrated into the design rules during data preparation to ensure seamless and efficient production.

Creo extension for additive manufacturing

The Creo additive manufacturing extension simplifies the process of designing, 3D printing and post-processing by integrating these functions into the familiar software environment. Users can work seamlessly within a single system, simplifying the workflow and increasing efficiency.

All-in-one solution

Intuitive and associative

CAD-To-Additives

in familiar surroundings

More than usual

Support geometry rethought

Post-processing

Seamless