Additive manufacturing service

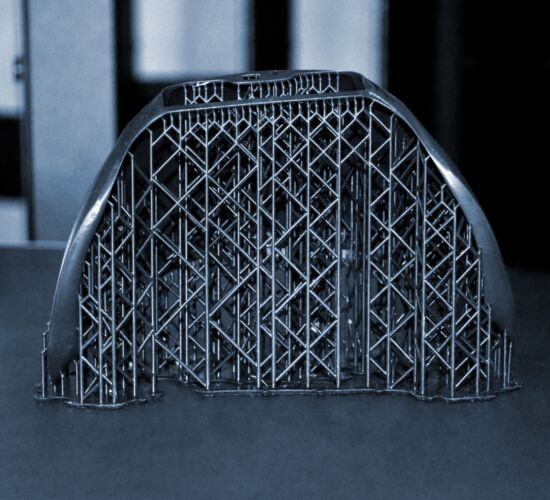

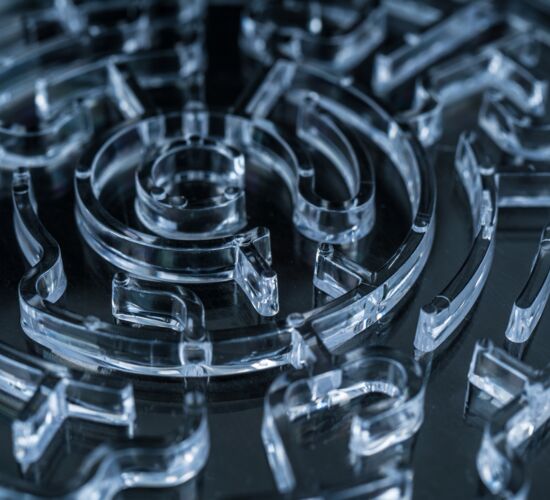

Additive manufacturing is now in full swing, driven by the ever-increasing speed of additive 3D printing and the development of production-ready materials. Early rapid prototype systems typically produced only a few samples at a time. Today, rapid production runs of 50 to 1,500 pieces for the end user are usually produced in just a few days, sometimes even hours. Unlike traditional "subtractive" methods, additive manufacturing enables the creation of complex geometries at no additional cost. Engineers are only limited by their imagination when designing new parts. Stereolithography, selective laser sintering, fused deposition modeling, carbon DLS

Other technologies are extending the reach of additive manufacturing. Precise laser scanning has become an important partner for 3D manufacturing as it enables scanning and duplication of legacy and pre-CAD parts with little effort. With our in-house 3D printers and scanners, LayerByLayer can work with you on all your additive manufacturing needs.